- Home

-

About

-

Navigation

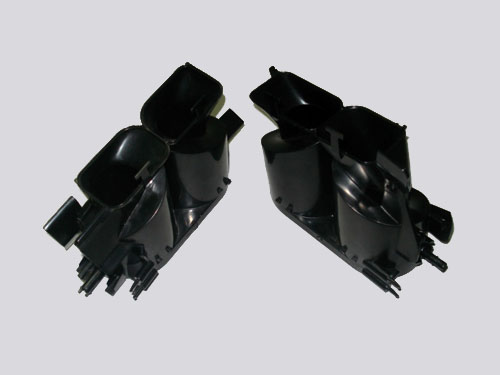

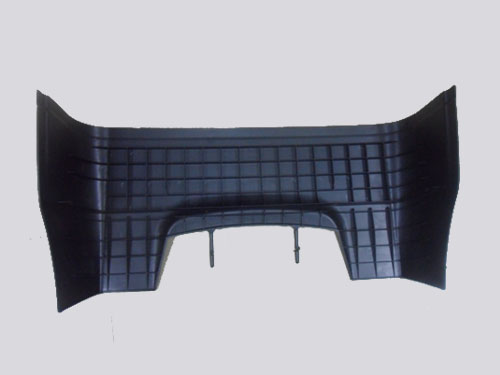

View More +About KaiyuDongguan KaiYu plastic mould co., LTD., founded in 2006, is located in changan town traffic convenience, wu sha community beach road no. 41, the company has professional equipment and perfect production process, the specialty is engaged in all kinds of precision plastic mold, metal mold design, development and manufacturing, products are mainly in automotive, home appliances, electronic accessories, such as mold...

-

-

Product

-

Navigation

View More +Recommended Products

-

- Application

-

News

-

Navigation

see more +Hot news2021-12-12First, raw materials This is the first problem to be noticed2021-12-12Main feature classification: 1. Classification according to2021-12-12The main component of automobile die is panel die. This kind2021-12-12Precision die processing is one of the most effective method

-

- Contact